| |

| |

| Names | |

|---|---|

| Other names

Lithium metatitanate

| |

| Identifiers | |

3D model (JSmol)

|

|

| ECHA InfoCard | 100.031.586 |

PubChem CID

|

|

CompTox Dashboard (EPA)

|

|

| |

| |

| Properties | |

| Li2TiO3 | |

| Molar mass | 109.76 |

| Appearance | White powder[1] |

| Density | 3.43 g/cm3[2] |

| Melting point | 1,533 °C (2,791 °F; 1,806 K)[1] |

| Structure[3] | |

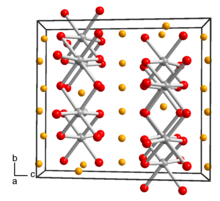

| Monoclinic, mS48, No. 15 | |

| C2/c | |

a = 0.505 nm, b = 0.876 nm, c = 0.968 nm α = 90°°, β = 100°°, γ = 90°°

| |

Lattice volume (V)

|

0.4217 nm3 |

Formula units (Z)

|

8 |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Lithium titanates are chemical compounds of lithium, titanium and oxygen. They are mixed oxides and belong to the titanates. The most important lithium titanates are:

- lithium titanate spinel, Li4Ti5O12 and the related compounds up to Li7Ti5O12. These titanates are used in lithium-titanate batteries.

- lithium metatitanate, a compound with the chemical formula Li2TiO3 and a melting point of 1,533 °C (2,791 °F)[4] It is a white powder with possible applications in tritium breeding materials in nuclear fusion applications.

Other lithium titanates, i.e. mixed oxides of the system Li2O–TiO2, are:

- Lithium orthotitanate Li4TiO4, melting point of 1,200 °C (2,190 °F)[4]

- Ramsdellite lithium titanate Li2Ti3O7 and LixTiO2 (0 ≦ x ≦ 0.57) with ramsdellite structure.[5]

Lithium metatitanate[edit]

Lithium metatitanate is a compound with the chemical formula Li2TiO3. It is a white powder with a melting point of 1,533 °C (2,791 °F).[4] It is also used as an additive in porcelain enamels and ceramic insulating bodies based on titanates. It is frequently utilized as a flux due to its good stability.[6] In recent years, along with other lithium ceramics, metatitanate pebbles have been the subject of research efforts towards tritium breeding materials in nuclear fusion applications.[7]

Crystallization[edit]

The most stable lithium titanate phase is β-Li2TiO3 that belongs to the monoclinic system.[8] A high-temperature cubic phase exhibiting solid-solution type behavior is referred to as γ-Li2TiO3 and is known to form reversibly above temperatures in the range 1150-1250 °C.[9] A metastable cubic phase, isostructural with γ-Li2TiO3 is referred to as α-Li2TiO3; it is formed at low temperatures, and transforms to the more stable β-phase upon heating to 400 °C.[10]

Uses in sintering[edit]

The sintering process is taking a powder, putting it into a mold and heating it to below its melting point. Sintering is based on atomic diffusion, the atoms in the powder particle diffuse into surrounding particles eventually forming a solid or porous material.

It has been discovered that Li2TiO3 powders have a high purity and good sintering ability.[11]

Uses as a cathode[edit]

Molten carbonate fuel cells[edit]

Lithium titanate is used as a cathode in layer one of a double layer cathode for molten carbonate fuel cells. These fuel cells have two material layers, layer 1 and layer 2, which allow for the production of high power molten carbonate fuel cells that work more efficiently.[12]

Lithium-ion batteries[edit]

Li2TiO3 is used in the cathode of some lithium-ion batteries, along with an aqueous binder and a conducting agent. Li2TiO3 is used because it is capable of stabilizing the high capacity cathode conducting agents; LiMO2 (M=Fe, Mn, Cr, Ni). Li2TiO3 and the conduction agents (LiMO2) are layered in order to create the cathode material. These layers allow for the occurrence of lithium diffusion.

Lithium-titanate battery[edit]

The lithium-titanate battery is a rechargeable battery that is much faster to charge than other lithium-ion batteries. It differs from other lithium-ion batteries because it uses lithium-titanate on the anode surface rather than carbon. This is advantageous because it does not create a solid electrolyte interface layer, which acts as a barrier to the ingress and egress of Li-ion to and from the anode. This allows lithium-titanate batteries to be recharged more quickly and provide higher currents when necessary. A disadvantage of the lithium-titanate battery is a much lower capacity and voltage than the conventional lithium-ion battery. The lithium-titanate battery is currently being used in battery electric vehicles[citation needed] and other specialist applications.

Tritium breeding[edit]

Fusion reactions, such as those in the proposed ITER thermonuclear demonstrator reactor, are fueled by tritium and deuterium. Tritium resources are extremely limited in their availability, with total resources currently estimated at twenty kilograms. Lithium-containing ceramic pebbles can be used as solid breeder materials in a component known as a helium-cooled breeder blanket for the production of tritium.[13] The breeding blanket constitutes a key component of the ITER reactor design. In such reactor designs tritium is produced by neutrons leaving the plasma and interacting with lithium in the blanket. Li2TiO3 along with Li4SiO4 are attractive as tritium breeding materials because they exhibit high tritium release, low activation, and chemical stability.[7]

Synthesis of lithium-titanate breeder powder[edit]

Li2TiO3 powder is most commonly prepared by the mixing of lithium carbonate, Ti-nitrate solution, and citric acid followed by calcination, compaction, and sintering. The nanocrystalline material created is used as a breeder powder due to its high purity and activity.[14][12][15]

See also[edit]

References[edit]

- ^ a b Hanaor, Dorian A.H.; Kolb, Matthias H.H.; Gan, Yixiang; Kamlah, Marc; Knitter, Regina (2014). "Solution based synthesis of mixed-phase materials in the Li2TiO3-Li4SiO4 system". Journal of Nuclear Materials. 456: 151–161. arXiv:1410.7128. Bibcode:2015JNuM..456..151H. doi:10.1016/j.jnucmat.2014.09.028. S2CID 94426898.

- ^ Van Der Laan, J.G; Muis, R.P (1999). "Properties of lithium metatitanate pebbles produced by a wet process". Journal of Nuclear Materials. 271–272: 401–404. Bibcode:1999JNuM..271..401V. doi:10.1016/S0022-3115(98)00794-6.

- ^ Claverie J., Foussier C., Hagenmuller P. (1966) Bull. Soc. Chim. Fr. 244-246

- ^ a b c Dorian Hanaor; Matthias Kolb; Yixiang Gan; Marc Kamlah; Regina Knitter (2014). "Mixed phase materials in the Li4SiO4 Li2TiO3 system". Journal of Nucl Materials. 456: 151–166.

- ^ Tsuyumoto, Isao; Moriguchi, Takumi (October 2015). "Synthesis and lithium insertion properties of ramsdellite LixTiO2 anode materials". Materials Research Bulletin. 70: 748–752. doi:10.1016/j.materresbull.2015.06.014.

- ^ "Lithium Titanate Fact Sheet". Product Code: LI2TI03. Thermograde. Archived from the original on 23 March 2011. Retrieved 24 June 2010.

- ^ a b Hanaor, D. A. H.; Kolb, M. H. H.; Gan, Y.; Kamlah, M.; Knitter, R. (2014). "Solution based synthesis of mixed-phase materials in the Li2TiO3-Li4SiO4 system". Journal of Nuclear Materials. 456: 151–161. arXiv:1410.7128. Bibcode:2015JNuM..456..151H. doi:10.1016/j.jnucmat.2014.09.028. S2CID 94426898.

- ^ Vijayakumar M.; Kerisit, S.; Yang, Z.; Graff, G. L.; Liu, J.; Sears, J. A.; Burton, S. D.; Rosso, K. M.; Hu, J. (2009). "Combined 6,7Li NMR and Molecular Dynamics Study of Li Diffusion in Li2TiO3". Journal of Physical Chemistry. 113 (46): 20108–20116. doi:10.1021/jp9072125.

- ^ Kleykamp, H (2002). "Phase equilibria in the Li–Ti–O system and physical properties of Li2TiO3". Fusion Engineering and Design. 61: 361–366. doi:10.1016/S0920-3796(02)00120-5.

- ^ Laumann, Andreas; Jensen, Ørnsbjerg; Kirsten, Marie; Tyrsted, Christoffer (2011). "In‐situ Synchrotron X‐ray Diffraction Study of the Formation of Cubic Li2TiO3 Under Hydrothermal Conditions". Eur. J. Inorg. Chem. 2011 (14): 2221–2226. doi:10.1002/ejic.201001133.

- ^ A. Shrivastava; T. Kumar; R. Shukla; P. Chaudhuri (July 2021). "Li2TiO3 pebble fabrication by freeze granulation & freeze drying method". Fusion Eng. Des. 168: 112411. doi:10.1016/j.fusengdes.2021.112411. S2CID 233544019. Retrieved 27 March 2022.

- ^ a b Prohaska, Armin et al. (1997) U.S. patent 6,420,062 "Double layer cathode for molten carbonate fuel cells and method for producing the same"

- ^ A. Shrivastava; R. Shukla; P. Chaudhuri (May 2021). "Effect of porosity on thermal conductivity of Li2TiO3 ceramic compact". Fusion Eng. Des. 166: 112318. doi:10.1016/j.fusengdes.2021.112318. S2CID 234865541.

- ^ A. Shrivastava, T. Kumar, R. Shukla, P. Chaudhuri, Li2TiO3 pebble fabrication by freeze granulation & freeze drying method, Fusion Eng. Des. 168 (2021) 112411. https://doi.org/10.1016/j.fusengdes.2021.112411.

- ^ Shrivastava, A.; Makwana, M.; Chaudhuri, P.; Rajendrakumar, E. (2014). "Preparation and Characterization of the Lithium Metatitanate Ceramics by Solution-Combustion Method for Indian LLCB TBM". Fusion Science and Technology. 65 (2): 319–324. Bibcode:2014FuST...65..319S. doi:10.13182/FST13-658. S2CID 123286397.